My 'First in the U.S.A.', Elsbett single tank DIY VW TDI

conversion.

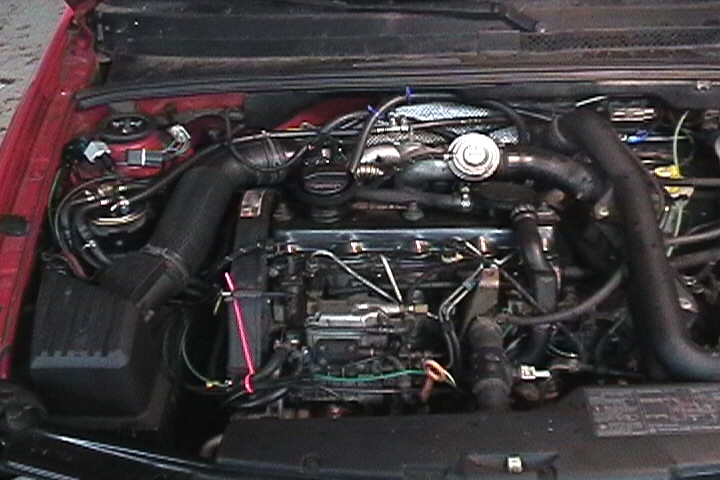

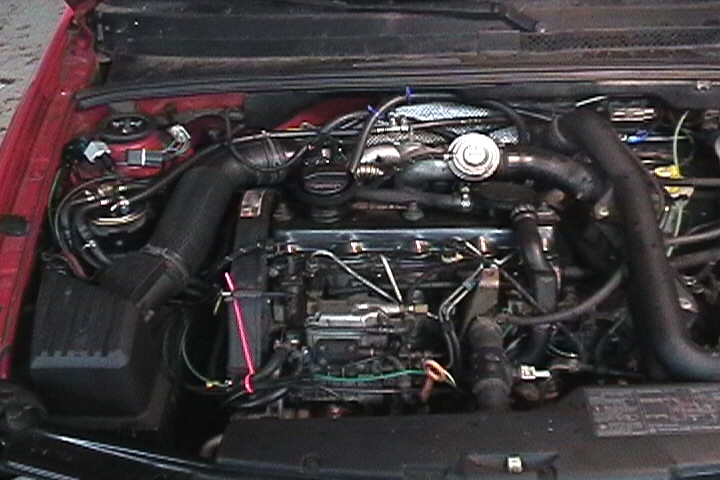

Above is the left side of engine compartment. The modified

injectors and new glow plugs are already installed. Elsbett

generously provided new inter injector fuel lines too. Visible at the top

above the EGR valve is the coolant lines that "T" into the cabin heater

hoses. They have blue tie-wraps. Above and to the left , the shiny "T"

fuel line fitting which leads from the coolant heater ( not visible )

to the fuel filters on either shock tower. To the right of the EGR

valve is a blue inline splice for wiring into the coolant relay just

above the splice. On the left side, the electric fuel filter heater is

around the std. fuel filter ( not visible ). Above the f.f. is the 3

relays that control the f.f. heater, and engine and coolant glow plugs.

Below the fuel pump you can see a new fuel line warpped in pink

tie-wrap. A green wire leads right to left to the thermoswitch mounted

on the back of the oil filter housing. Not visible are the wires to the

alternator, fuel solenoid and coolant temperature sensor.

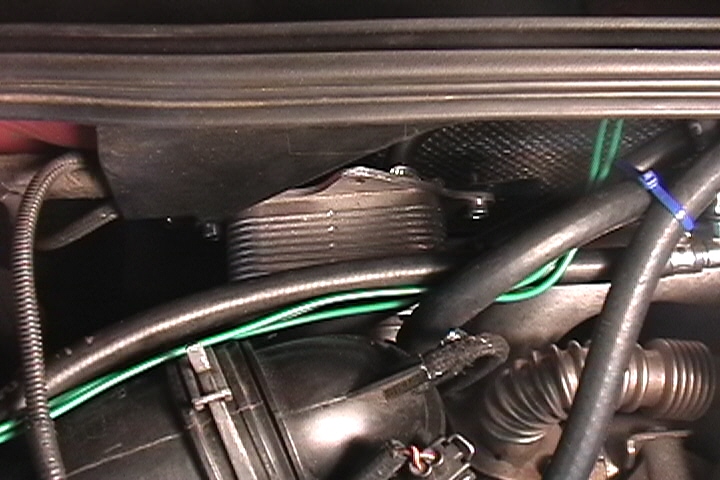

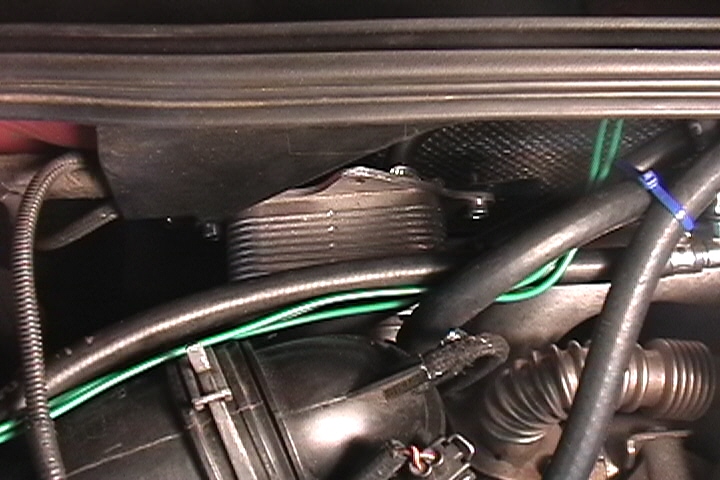

On ethe right shock tower is where I mounted the spare fuel

filter. There is little room under the hood, and this spot had the

room, PLUS, two bolts were ALREADY THERE for mounting a fuel filter

clamp! VW must have provisiond for f.f.'s at either side. Note the

shutoff valve to the right of the coolant resevoir. To place the f.f. clamp

here I had to swing the +12V battery clamp counter clockwise. It just

fits between the coolant hose and fuse block.

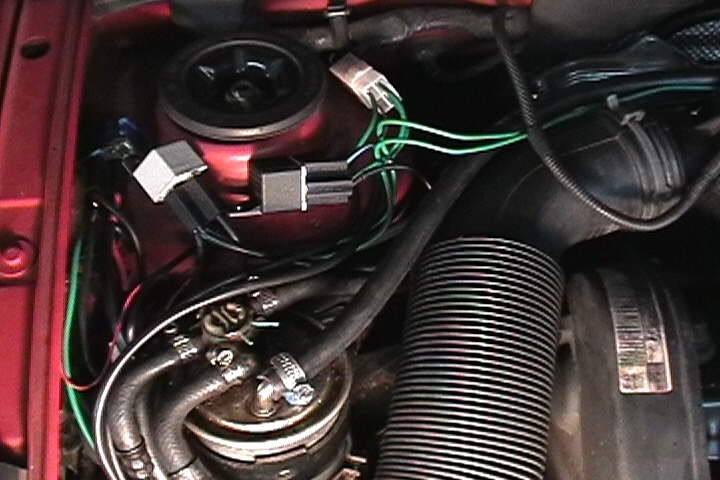

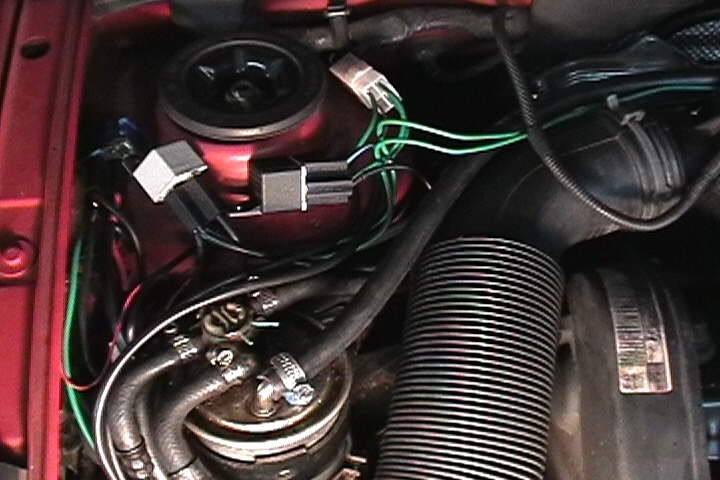

This is the coolant fuel heater. It's small, about the size of 2

cigarette packs. It's up against the firewall on the left side, behind

the air intake tube. I made a bracket out of a 2" x 12" piece of

galvanized strapping. It mounts to a bolt that holds the A/C lines to

the firewall. I lost the original nut to the engine pan. :( It's a 6mm

nut. Planning and fabricating this bracket took 3-4 hours. I'm not

entirely satisfied. While all hoses clear, there may be some chaffing

to worry about. Diesels vibrate a lot and this can cause chaffing of

hoses and plastic parts. I made a copper shield to wrap around hoses

that rubbed against sharp metal edges. Elsbett recommends placing this

below and to the left of the brake booster, but I couldn't find any

suitable mounting points. Wherever it goes, you'll have to make your

own bracket.

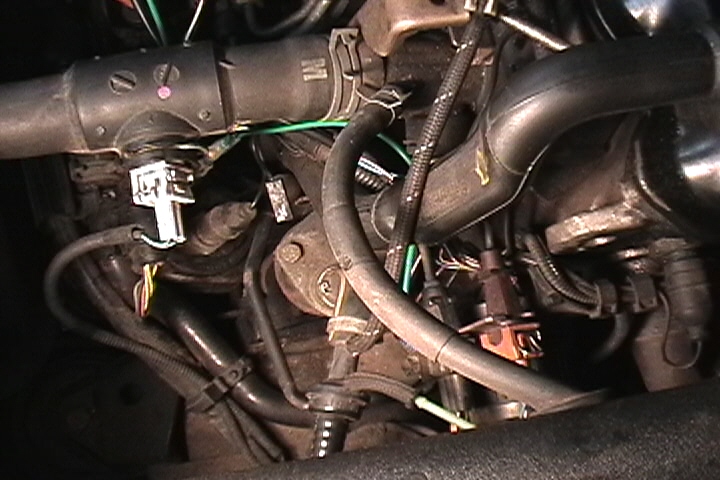

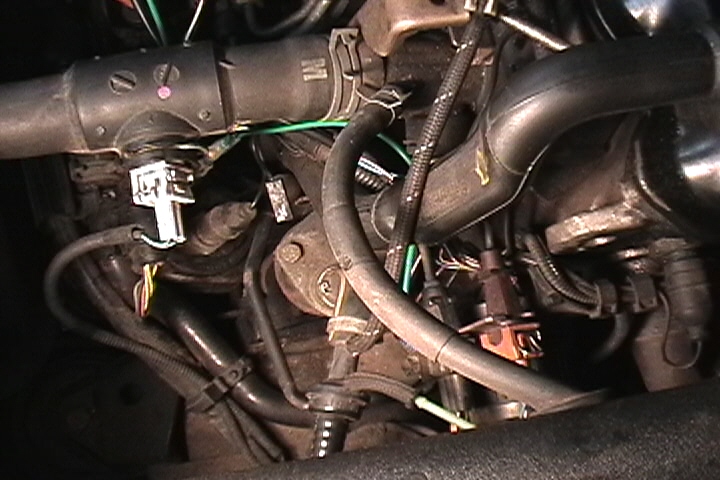

The 3 control relays. Unfinished, just laying on the left shock

tower. I'll mount them with rubber to isolate them from vibration.

Just behind ( not visible )the bright white electrical connector is the

thermoswitch that controls the electrics. Follow the green wire right to

left. Also not visible are 2 inline splices to the engine coolant

sensor in the lower right portion of the picture. Also a green wire.